Before you buy / Technical Questions

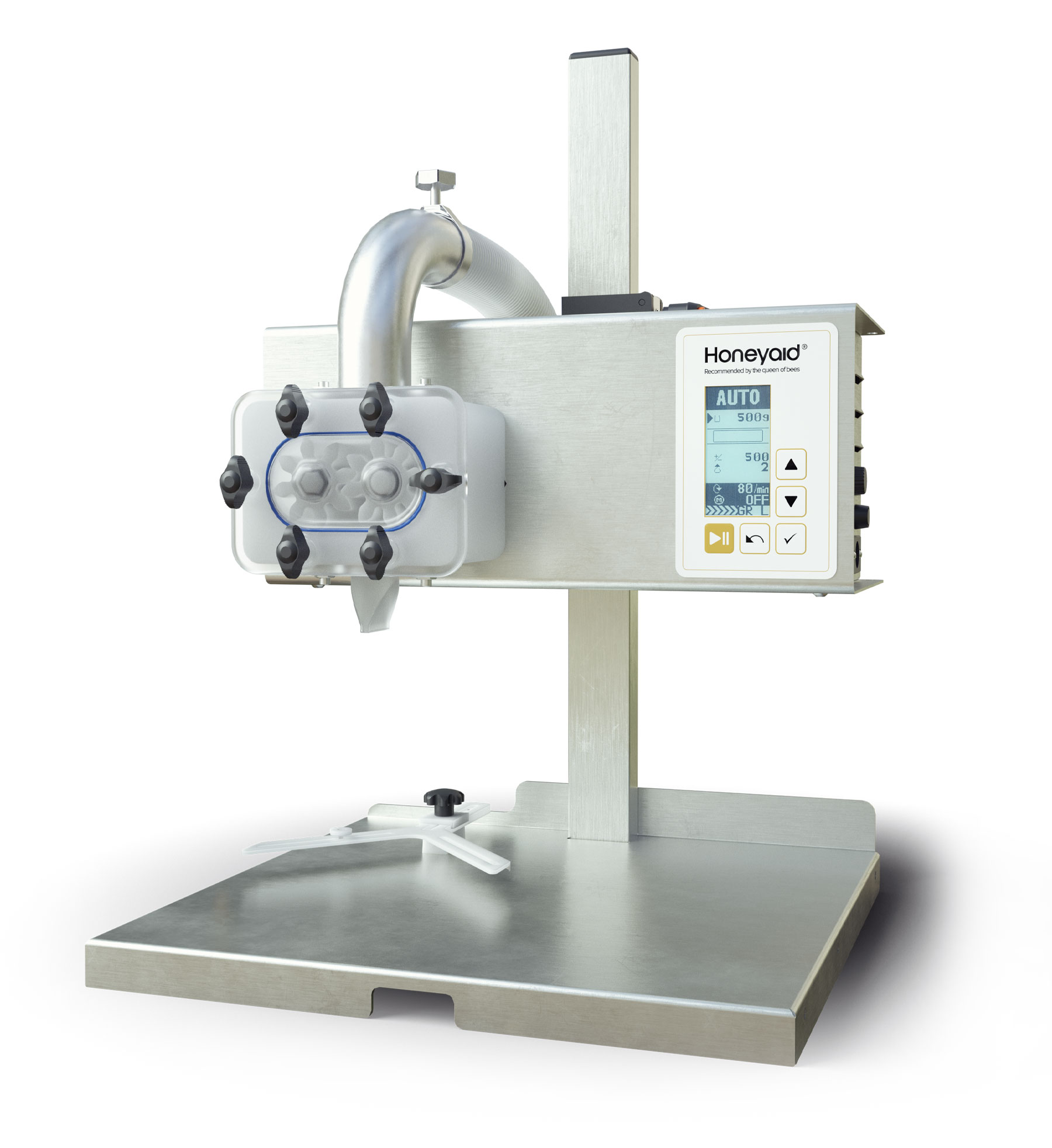

The performance and throughput depend on your honey’s viscosity and the size of the containers to be filled. The machine can generally fill about 400 jars of 500g per hour.

The machines can be programmed in increments of 0.1g up to a quantity of 50g and from 50g in increments of 1g up to 32kg. However, we recommend jar sizes starting from 30g.

This is fine in the majority of cases. We will be happy to help you select the correct valve/connection. We already have some standard connections in our stock.

The Honeyaid® machines are volumetric fillers, i.e., the pumps determine the volume filled by the number of revolutions. The machine is calibrated to your current honey at the beginning of each filling operation. This process takes less than 5 minutes, and your machine is ready for use, filling with an accuracy of +/- 2%.

No. We advise all our customers to calibrate and randomly check the fillings with a calibrated scale.

Yes. All product-contact parts used for filling food are food-safe.

Please ask us if you need a special certificate for any product.

Yes. The machine provides input and output signals needed for integration into a PLC.

The accuracy varies from 1% to a maximum of 2%, which is within the scope of the legal regulations.

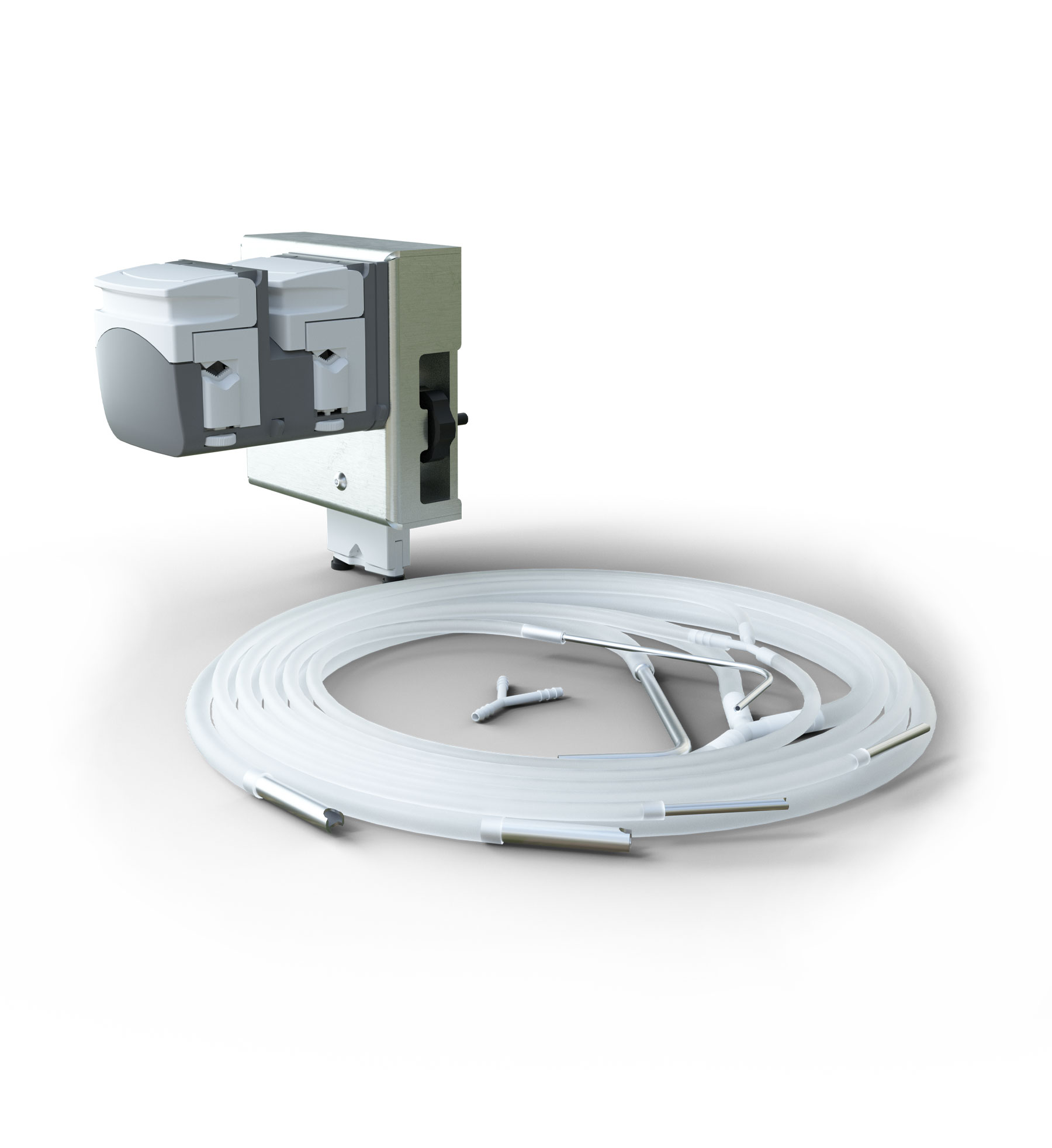

The machine must be cleaned after each use. All parts that come into contact with the product can be removed and disassembled within five minutes. These parts can then be cleaned, for example, in the dishwasher.

We recommend replacing all seals every 20,000 kg or at least once a year.

Apart from that, our machines are very low maintenance, but if you wish, you can send us your machine for inspection anytime.

Yes, we have all spare parts in stock. This particularly includes our first DS 10000 filling machine, which has not been for sale since 2009.

Our filling systems are extremely durable. Thanks to the well-thought-out design, worn or defective parts can easily be replaced without needing to invest in a whole new machine. However, regular maintenance is a prerequisite for a long service life. For example, we know machines that have already filled more than 3,000,000 kg.

Your first point of contact is the dealer from whom you purchased the machine. He will help you with any questions or problems. However, you are also welcome to contact us if you need help with your machine.

The machine comes with a comprehensive manual that describes the structure in detail. If you have any problems assembling or filling the machine for the first time, you can contact us and we will be glad to help you.

Our filling systems require a footprint of around 60 cm2.

Operation with a solar panel is possible in principle. Unfortunately, we do not offer any suitable module ourselves yet, but this is a work in progress.

Questions about machine use

Your bottlingmachine comes with a manual that describes this step in detail. If you still have problems, please get in touch with your dealer or us.

All parts that come into contact with the product can be removed and disassembled within five minutes. These parts can then be cleaned in the dishwasher.

If you have any problems, your dealer will be happy to help. Please describe the error as precisely as possible. Has there been a change in your processes or product? Together, we will find a solution.

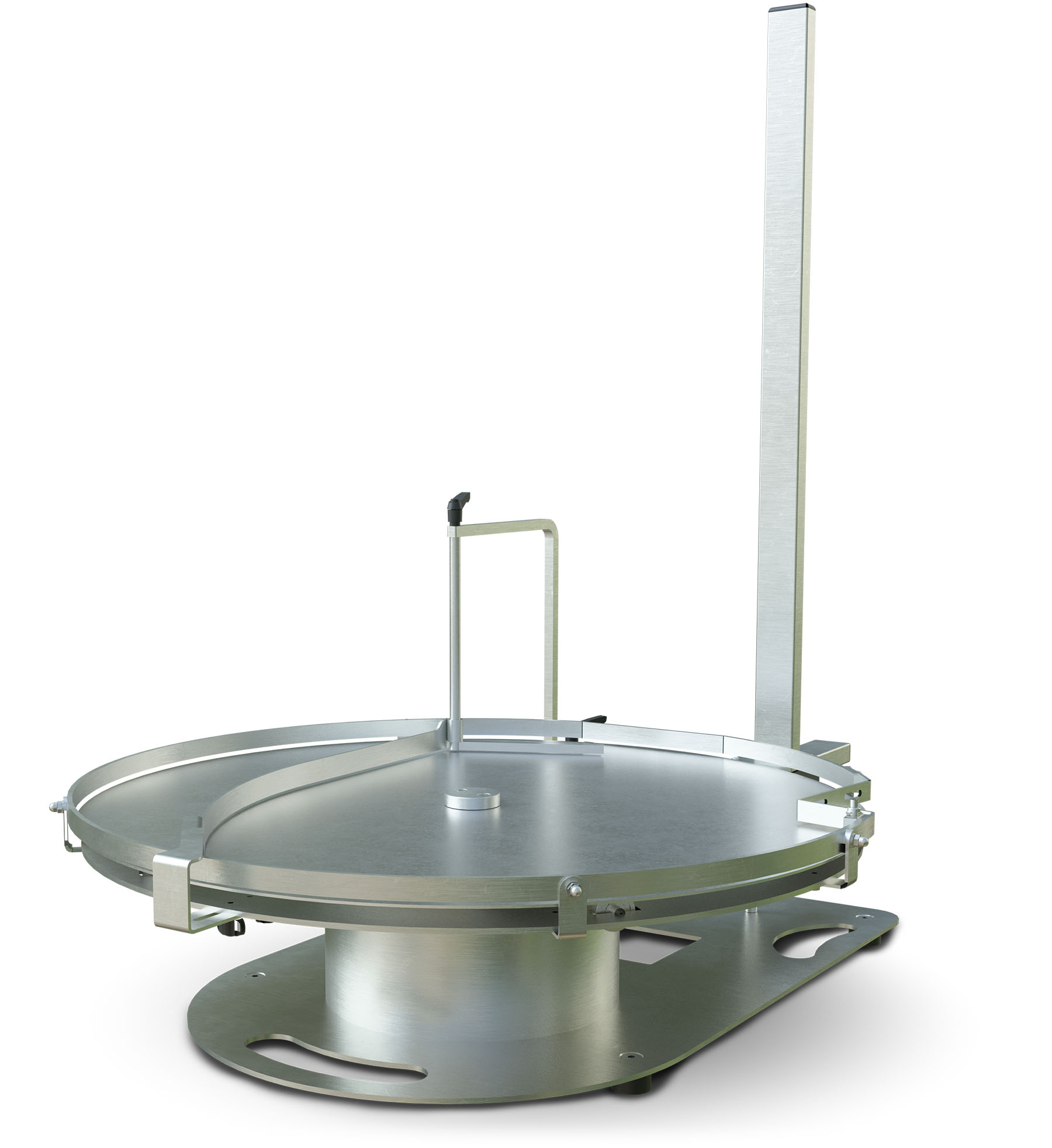

On the pages Automation modules and Extension sets, we inform you about the possibilities of automating your production process so that you can adapt it to your increased production volume. There are also numerous conversion options for our machines, and your dealer will be happy to advise you in detail.

Please get in touch with the dealer from whom you purchased the machine or use our online shop to order the needed parts.

You still have a Question?

Please use our contact form below and send us your question. We will answer your request as soon as possible.